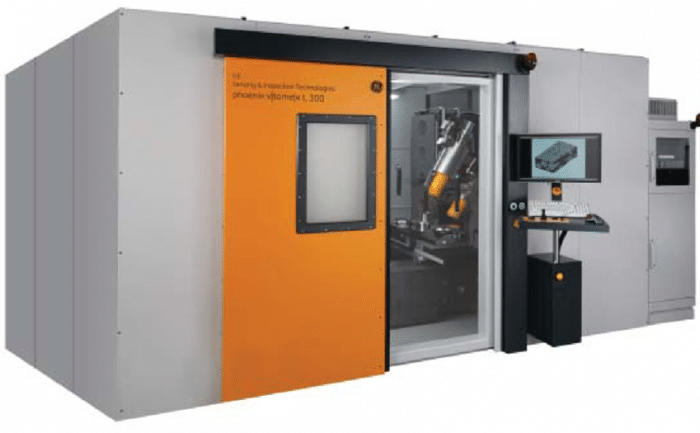

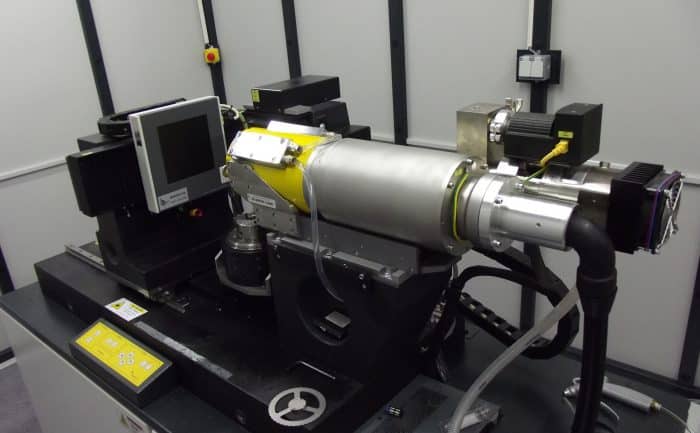

Industrial CT Scanning & X-ray Solutions

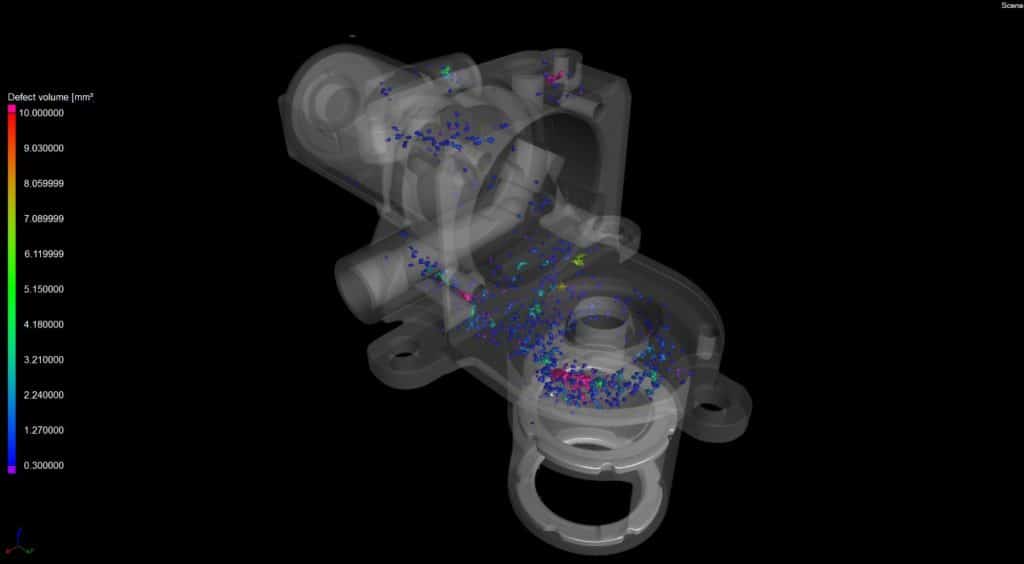

State-of-the-art X-ray tomographic imaging facilities for industry and academia. We can support research and RTD projects in a variety of disciplines such as materials science, engineering, biomedical imaging and electronics.