Industry: Polymers / Plastics Manufacturing

Problem: Polyacetal, also referred to as acetal or polyoxymethylene (POM), is a high-performance engineering thermoplastic known for its high strength, dimensional stability, low friction, and strong wear resistance. However, after introducing a new polyacetal resin batch to a production process, the failure rate of mechanical components increased dramatically.

Solution: SEAM performed two materials analysis techniques; Fourier Transform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC), to determine compositional differences between a failed component and a control sample.

The polymers were first characterised using FTIR to determine their chemical composition. Samples were analysed using a Bruker Lumos II FTIR Microscope, in direct contact with the ATR crystal and then compared against a reference database for quick identification. There were no obvious differences between a control and the failed component (Fig 1). The reference library indicates that both samples are consistent with polyoxymethylene, as expected (Fig 2).

Figure 1: Overlay of ATR-FTIR spectra of control and failed samples.

Figure 2: Match of spectrum with reference library – polyoxymethylene (POM) match.

The polymers were then analysed using Differential Scanning Calorimetry (TA Instruments DSC250) to study the crystalline properties. A small amount of material (10 mgs) was isolated from the failure region on the samples and heated from room temperature to 220°C, at a heating rate of 10°C/min. This was then repeated for the known good sample (control). The results (Fig 3.) indicate a marked difference in peak melt temperature of the polymer (12°C lower than the control).

Figure 3: Overlay of DSC heating cycles of control and failed POM samples.

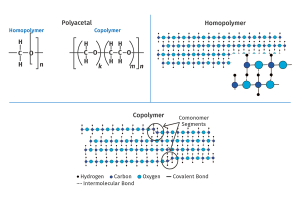

Polyacetal polymers typically come in two forms, Homopolymer and Copolymer (Fig 4.). Homopolymers are made from a single monomer [-CH2O-], resulting in higher crystallinity and superior mechanical properties like increased stiffness, strength, and hardness. Copolymer polyacetal was not detectable in FTIR analysis but can easily be distinguished using DSC.

Figure 4: Polyacetal homopolymer and copolymers

Conclusion:

A failed component was analysed and compared with a control sample. It was determined that the failed sample was a polyacetal copolymer and the control sample was a polyacetal homopolymer. If the application requires maximum strength, wear resistance, or minimal deformation under load, switching to a copolymer with reduced mechanical properties can result in failure of the part.

This piece was written by Dr. Colin Reidy & Malgorzata Markowska . If you would like to learn more about the analysis or capability at SEAM please contact us.